This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Contact us for further information

Linear Guide Solutions

When we require solutions about linear movements, surely you know some products, but we may not take into account all the solutions we have at our disposal.

First of all we must know the ball screws, which as we can deduce, it is a linear actuator responsible for converting the circular or rotational movement, in linear movement, always with the minimum loss of friction. It is like a screw, which can be found in different sizes and diameters, and has multiple applications, either in presses, jaws, milling machines or hydraulic gates.

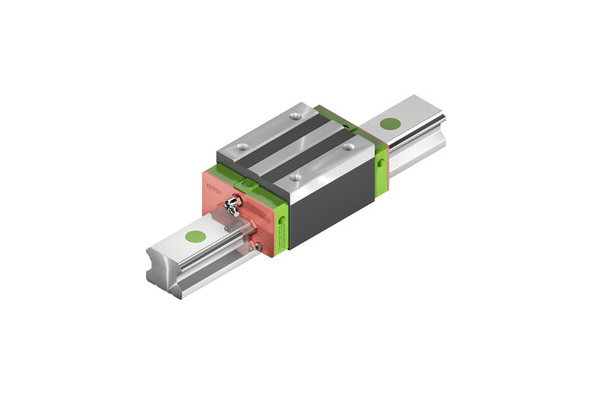

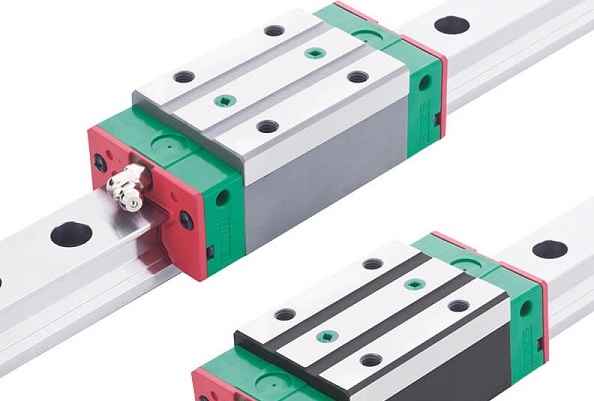

Another solution we find for linear movement are linear guides, devices widely used in the industry, but of which there are surely many details that we do not know, or that we overlook.

First of all, we must know that we can find linear guides in very short lengths, and in very large ones, of more than 2 meters, which shows us that they can cover a very large range of motion, depending on our specific needs.

The main characteristic of the linear guides is that they will help us to achieve the translation between pieces, always with the minimum loss of friction, and in addition, they will also be able to withstand the forces acting in a direction perpendicular to their placement.

Another aspect that we must know is that we can find different linear guidance systems, depending on how it carries out the translation between pieces, distinguishing between three large groups.

First, we find the linear contact guides, in which the contact of these guides and the other body is direct, although it is possible that between both there is some type of coating to further minimize the friction between them.

Secondly, we find the linear guides with bearings, which are all those that use rollers, also called balls, rollers or wheels, which are between the two solid bodies, being responsible for reducing friction between them.

Finally, we find the hydrostatic linear guides, in which between the two bodies instead of finding a solid component, we find some type of fluid under pressure, which can be for example air or oil. This fluid will prevent the two bodies from coming into contact, thereby reducing friction.

Linear guides in Dynamics

In Dinámica we have various linear movement solutions to meet whatever your need, always using the best technologies to offer you the best possible result.

All our linear motion solutions have been made using the best possible materials, to guarantee the highest quality of all our products. Among all of them you will find ball screws, intelligent guides and skates, measuring systems and Wafer Robot.

In Dinámica we have personalized attention, thanks to our human team that will anticipate the specific needs that you want to cover of your project. We will be happy to advise you in order to offer you the best, most effective and cost-effective solution for your specific situation.

Different types of linear guides

As for the linear guides, first of all we must mention the linear guides of rollers, whether flat, Gothic arch or type V. All of them are widely used to carry out all kinds of guides that require resistance, with a simple and economical installation and with simple maintenance.

We must also talk about ball recirculation guides, which have a very simple assembly, being one of the most popular solutions in the industry.

Another widely used linear guide is the roller recirculation, among which we differentiate the prismatic guide with skid and the cross roller guide. Both are widely used in those sectors where very heavy machinery is used.

The friction guides are the next on the list, and we must emphasize that they are the oldest used in engineering, being very popular in mechanisms that present few movements.

We also find the linear guides of air bearings, which have a simple mechanism, offering excellent precision of movement.

Finally, we will talk about hydrostatic guides, widely popular in machine tool applications. These guides focus their operation on the fact that the space between the guide and the skid has been filled with an oil film, making friction but without physical contact between the parts.

Catalog of solutions for linear guides of Dynamics

Within the wide catalog of linear movement solutions of Dynamics, we can find:

- Hiwin Spindles KK Axis Robot sets, which are characterized by having a slider driven by a motorized type spindle and guided by a linear guide rail.

- Hiwin GBS Precision Grinding Spindles, high precision, high speed, which will provide us with low drive noise.

- Hiwin HEAVY LOAD spindles Heavy loads, for high speed operations, achieving a long service life.

- Hiwin COOL TYPE II Protection spindles, which have an optimized design to achieve high reliability.

- Hiwin E-2 Self-lubricating spindles, through which we will save costs, thanks to the elimination of common piping systems, change and waste disposal.

- Hiwin RBS Lamidado High Speed spindle, for heavy loads, have a multi-load ball design.

- Hiwin COOL TYPE I spindles Thermal protection, with which we will achieve high reliability, allowing a higher rotation speed.

- Hiwin Super S spindles High degree of precision, thanks to which we will achieve a low noise level, with high acceleration and deceleration.

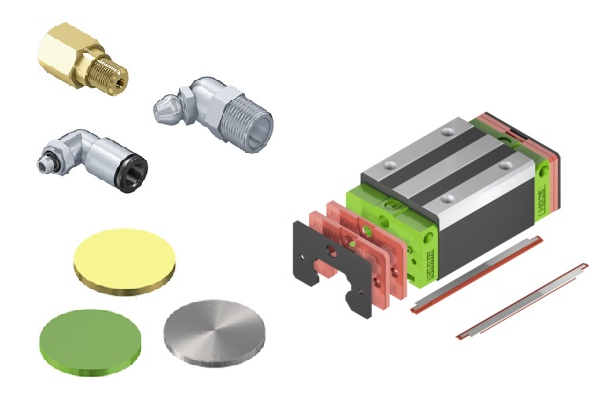

- Hiewin Miniature MG Series linear guide, an ideal solution for small equipment.

- Hiwin EG Series Linear Guide High rigidity, which offers a low profile, with a high load capacity, and high rigidity.

- Linear guide Hiwin HG Series High rigidity, thanks to which we will be able to absorb most of the installation errors and irregularity of the surface, providing a smooth linear movement, thanks to the elastic elements of the rolling.

- Hiwin PG Series linear guide with positioning guide, which has additional internal components, which saves space for installation.

- Linear guide Hiwin Series E2 Self-lubricating, which contain a lubricant between the end cap and the final seal.

- Hiwin Series Q1 SynchMotion TM linear guide, ideal for heavy loads, with a multi-load ball distribution design.

- Linear guide Hiwin RG Series With rollers, one that has a roller as a rolling element, instead of steel balls.

- Hiwin Linear Actuators, special for use in hospitals and industries with compact equipment.

- Hiwin Linear Motor, which will provide us with a smooth movement, with a compact design for movement in two axes.

- Hiwin Rotary Tables, which will guarantee excellent acceleration capacity and good uniformity of movements.

- Hiwin Linear scale system with LCD display, an ideal system for woodworking machines.

- Hiwin Magnetic Measurement System, which is an integrated linear guide assembly system, which has position measurement with magnetic encoder.

- Wafer Robot.