This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Other link

Nidec® VR series planetary gearboxes show excellent versatility combined with high quality; certified by a manufacturing process that includes constant quality controls of each component, and final tests of the complete product for angular reaction, noise, resistance of the bottom unit and resistance to slipping. Through the use of software-optimized helical gears, a superior tooth hardening process, and extremely close machining tolerances, we are able to deliver optimum power density to meet the most demanding requirements for dynamics and precision. Nidec® Planetary Gearboxes are interchangeable with most gearboxes on the market.

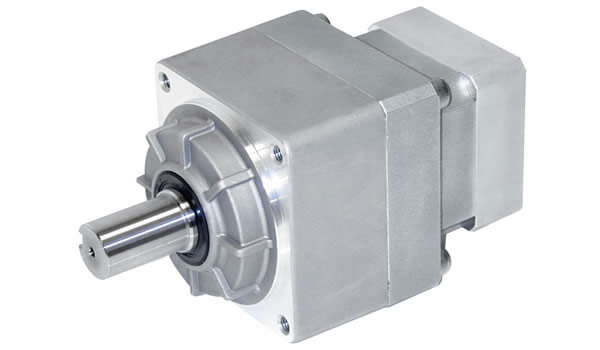

Inline Coaxial Epicycloidal Gearbox

VRL SeriesReliability Complete range of products

The Nidec® VRL series has dimensions that allow the Gearbox to be a direct replacement for some other common competitor models. The machining quality of the helical planetary gears includes a gearbox that is very quiet and more efficient than competitive products. These planetary gearboxes are the perfect solution for servo drive applications such as injection molding machines, picking automation, and linear devices.

VRB SeriesPrecision, easy mounting by square flange

A great alternative for OEMs who need a high performance gearbox with a flexible mounting design and ease of mounting the Gearbox on their machinery. Positional accuracy and torque handling capabilities are ideal for custom-built packaging machinery, medical equipment, and cell automation. The VRB series planetary gearbox and its standard mounting flange are a dimensional replacement for some common competitive models.

The VRB provides a reaction rating of 3 Arc/min. as their standard, which means this series provides solid performance at an exceptional value.

VRS SeriesHigh precision, versatility and high radial and axial load

This planetary series has exceptional load handling capabilities and is ideal for higher speed, continuous duty applications. Tapered roller bearings at the Gearbox output allow the VRS gearbox to handle larger thrust and radial loads. This internal design provides extremely smooth operation and a quiet gearbox even under high static forces. The VRS series is used in applications such as higher speed packaging and converting equipment, printing machinery and any servo application that requires very low reaction in a demanding environment.

Standard reaction is 3 arcs/min (one stage and two stage), ideal for higher levels of positional.

VRT SeriesCompact design, extreme performance with ISO flange

The VRT series sets the new standard for applications requiring extremely high torque ratings and rigidity. The compact design and hub-type output are ideal for equipment requiring high-speed, high-precision indexing motion. The torsional rigidity and low backlash of the planetary gear provide outstanding positioning accuracy.

With a recoil rating of less than 3 Arc/min. and exceptional torque handling capabilities, the VRT offers a robust, high performance planetary solution for OEM customers. The VRT Gearbox is suitable for larger applications of indexing and marking tables commonly found in packaging and filling equipment and assembly automation systems.

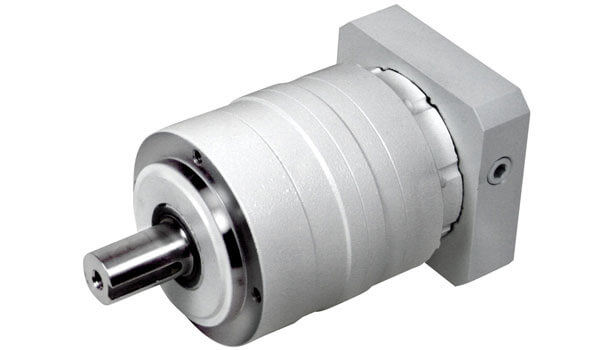

VRSF SeriesCompact lightweight aluminum frame

The VRSF uses a lightweight aluminum frame, helical cut gears, and a bearing stretch that provides the best level of precision and torque load capacity in its competitive class. The noise level generated by the VRSF is greatly reduced compared to competitive models based on spur gears.

The series is available in four frame sizes (B, C, D, E).

The VRSF can be selected with one of three levels of recoil: standard recoil at 15 arc/min, reduced recoil at 5 arc/min, and precision recoil at 3 arc/min.

Washdown SeriesOptional Features for Washed Feed Environments

Motion control applications in pharmaceutical, personal care, and food and beverage production environments require materials of construction and sealants that provide a higher degree of protection. To enhance our high precision product offering for customers in these industries, Nidec® now offers an a la carte washdown and food grade option for our inline and right angle planetary Gearbox.

These options provide maximum flexibility without sacrificing precision or performance. Different combinations of flush and feed level features include a stainless steel output shaft, SUS Ballscrews and bolts, sealed bearings, and an epoxy adhesive as a sealant. A package of food grade features includes a food grade white epoxy coating on the housing. Other custom coatings (ie Nickel Plated, Steel-it™, etc.) are available upon customer request.

These VRL and VRB inline frame sizes and ratios can be quickly assembled with any combination of the wash-on-demand or food-grade options.

- VRL Frame sizes: 070, 090, 120

- VRB – Frame sizes: 060, 090, 115

Quotient:

- One stage 3:1, 5:1, 7:1, 10:1

- Two stages 15:1, 25:1, 28:1, 30:1, 35:1, 50:1, 70:1, 100:1